Masters in air set casting

Delivering higher versatility

When your project requires prototyping or low- to -mid-volume runs, you need a precise casting process that delivers strength and flexibility, on your timeline. You need an air set aluminum casting from a partner with a proven process. That’s where Wisconsin Aluminum Foundry adds value.

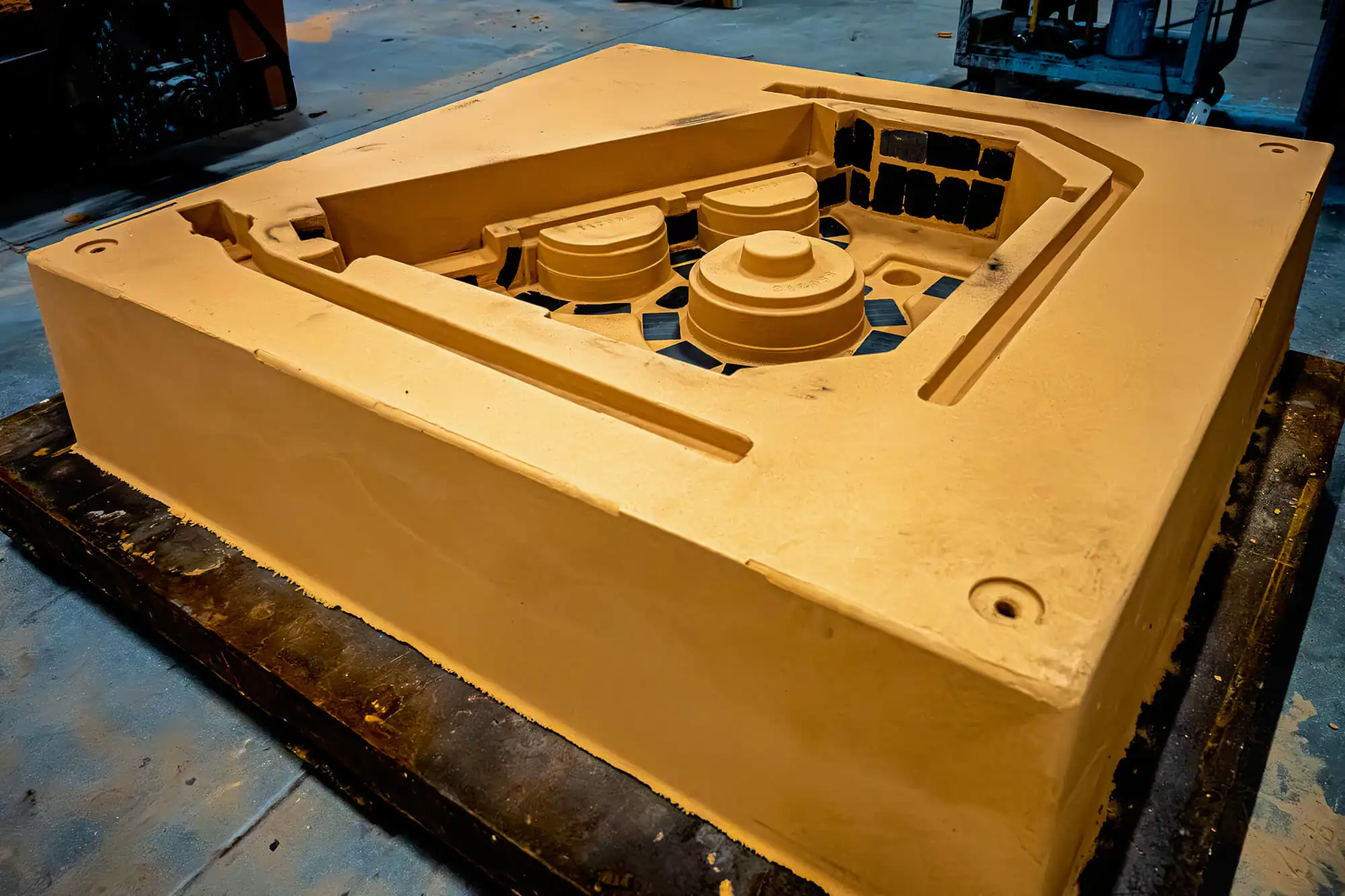

An air set casting partner making more castings possible

Wisconsin Aluminum Foundry’s air set aluminum casting method can produce castings from one to over 1,500 pounds. Also called a no-bake process, it offers a strong combination of complexity, dimensional accuracy and flexibility to produce virtually any size and weight of component for you. That includes tough construction parts, engine blocks and defense vehicle castings—precisely cast to exceed your expectations.

Top-quality air set molding

Some casting companies aren’t set up to solve what’s complex. If you’re looking for an intricate casting or a part with large dimensions, our chemically bonded sand molds provide the rigidity required to produce them to specifications—at varying sizes and configurations.

Precision-focused process

For higher dimensional accuracy in designs with deep, narrow pockets, we place chemically bonded sand inside a pattern to create molds that are used to produce some of the world’s toughest aluminum parts, across industries like heavy truck, construction and off-highway and defense.

Higher dimensional capabilities

WAF uses equipment that can handle the largest of molds, so you’re not limited by size. And because air set molding is so precise, you can cast aside any doubt about getting an accurate casting regardless of part size or complexity.

Smooth casting finishes

Chemically bonded sand provides your air set casting with a surface finish so smooth, the value is plain to see.

See what components we make possible with air set casting

Curious how air set sand casting or other aluminum casting methods can exceed your expectations? Get in touch.