Exceptional Service Across Industries

We have extensive experience in the heavy duty truck, automotive, marine, oil, agriculture, defense, and medical industries, as well as others. If your casting demands specific requirements, we draw on our expertise to provide you with a solution and deliver it on time.

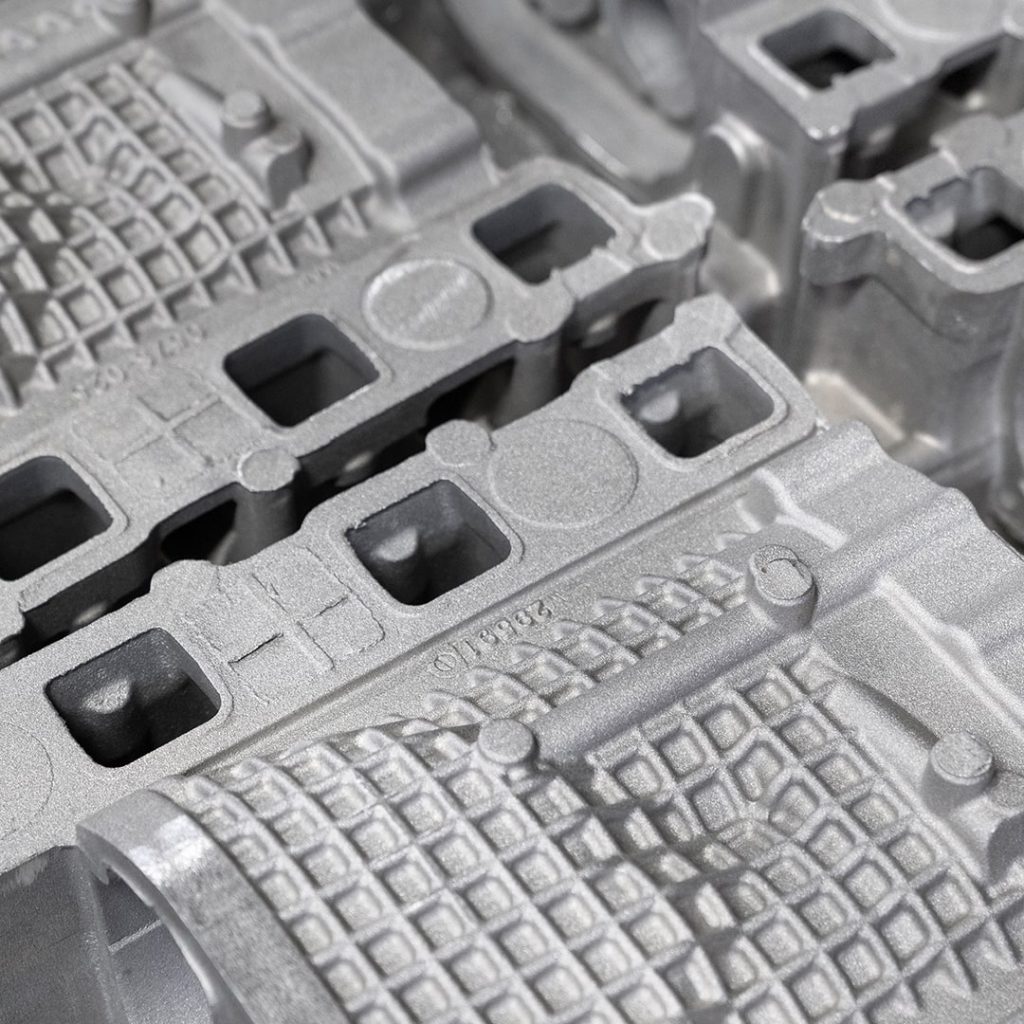

We accomplish this through our wide range of aluminum and bronze casting capabilities, machining and 100% vertical integration, including an in-house pattern shop, heat treating, impregnation, and our own machine shop.

Industries We Serve

Our aluminum and bronze castings provide high weight-to-strength ratios and non-corrosive characteristics, perfect for marine applications like pump housings, reservoirs, adapters, trim tabs, manifolds, and gear cases.

We provide aluminum castings critical to applications where fluid movement is required. Our castings help ensure the uninterrupted, day-to-day operation of buildings, platforms and airports, preventing safety hazards or product failures. ISO and environmental quality certifications mean you can be confident your castings are up to standard.

Our highly automated molding lines allow us to support programs that range from high-volume to low-volume aftermarket/high performance castings such as brackets, oil pump adapters, air inlets, intake manifolds, throttle bodies, water inlets and charge air cooler tanks.

We produce lightweight aluminum castings made from various alloys that will meet the strength and durability requirements of leading manufacturers in the agriculture industry. With the industry’s growing technology focus, aluminum is the future.

Take advantage of the benefits of corrosion resistant aluminum for your rail-related applications. We can provide a wide range of aluminum alloys to produce reliable, durable castings.

When it comes to castings for engine components, refrigeration, transmissions and braking systems, manufacturers of heavy-duty trucks depend on WAF for complete, structurally sound castings.

Our technical capabilities and quality systems help us produce critical component military parts for the defense industry.

Because durability is extremely important in the construction industry, manufacturers require parts that stand up to extreme conditions while meeting industry standards. Our process controls and state-of-the-art heat treatment furnaces allows us to achieve consistent mechanical properties to meet your needs.

Get in Touch

Don’t see your industry or want to learn more about how WAF can serve you? For 110+ years, Wisconsin Aluminum Foundry has developed a reputation of unmatched quality and delivery. Our customers expect the best, and we deliver custom components designed and manufactured for specific applications, servicing markets as diverse as heavy-duty truck, automotive, marine, oil, agriculture, defense and medical.