Wisconsin Aluminum Foundry, a non-ferrous castings company

Aluminum Elevated

When you have tough aluminum casting and copper-base casting challenges, you need a non-ferrous foundry partner who sees possibilities in every pour.

Since 1909, aluminum casting manufacturers with the most rigorous requirements have turned to Wisconsin Aluminum Foundry (WAF) to deliver. Our engineering team brings concepts to life using proven processes. And vertical integration provides exacting quality, industry-leading on-time delivery and lead times that meet demanding schedules.

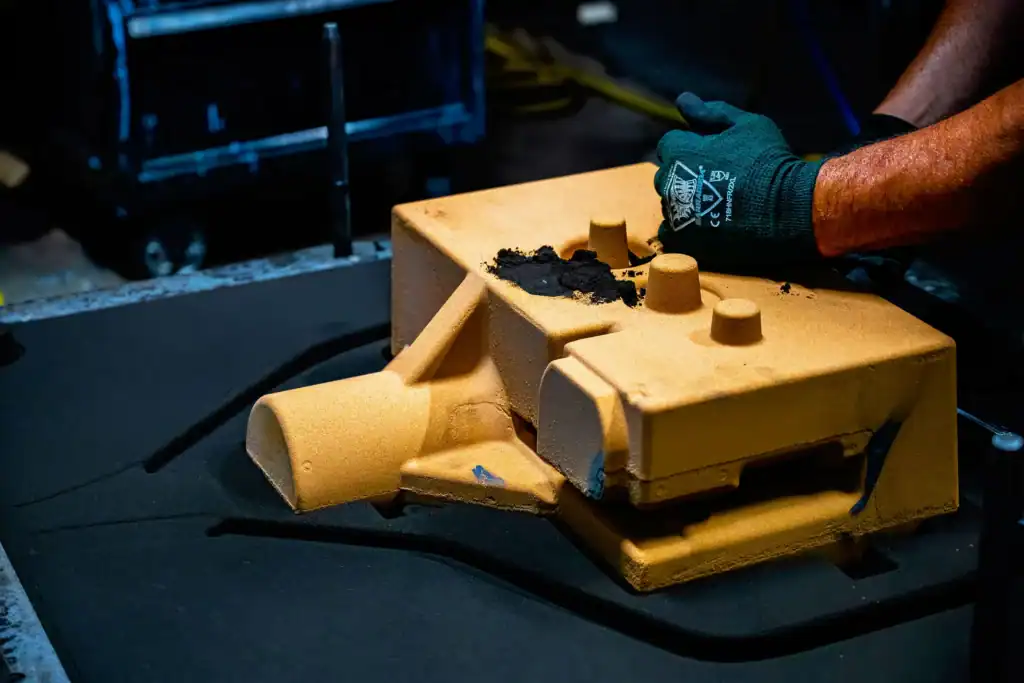

Watch our custom aluminum castings experts at work

The capabilities to cast better parts

With WAF, take your casting design from prototype to production tooling, with an engineering and manufacturing team driven to deliver. As a non-ferrous foundry, we offer a range of services in aluminum, bronze and brass castings, specializing in:

- Permanent mold casting

- Green sand casting

- Air set sand casting

- Low pressure permanent mold processes

- DISA molding and Hunter molding technologies and systems

A castings company with the means to deliver better solutions

Across Midwest locations, Wisconsin Aluminum Foundry stands ready to become your preferred aluminum castings supplier.

20+ Years

Average employment time at WAF

Industry leading

On-time delivery

World-class

Lead times

3x

Wisconsin Manufacturer of the Year

Higher-quality services across industries

Across industries, we’ve built a reputation among non-ferrous foundries for exceeding expectations with better on-time delivery and lead times, and higher-quality aluminum alloy castings, copper alloy castings, bronze and brass alloys. Expect custom components designed and manufactured to exacting applications, across markets as diverse as heavy-duty truck, automotive, marine, oil, agriculture, defense and medical.