The casting impregnation authority

If porosity issues continuously cause leaks, it’s time to fill in the gaps in your casting process. Choose a manufacturer that offers high-performance casting impregnation for leakproof parts and a streamlined program.

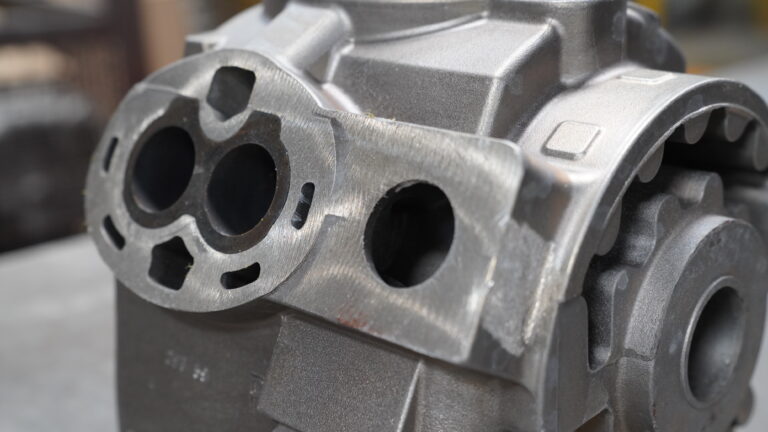

Powerful porosity sealing

When your castings risk microscopic holes that cause destructive leaks, Wisconsin Aluminum Foundry (WAF) addresses them onsite. Your dedicated WAF team uses a precise vacuum that produces exceptional leakproof components.

Capabilities like engineering and heat treatment allow our WAF team to produce components to porosity specifications. This streamlined approach reduces the need to coordinate production schedules with other vendors, giving you more reliable delivery schedules.

Casting impregnation services for superior performance

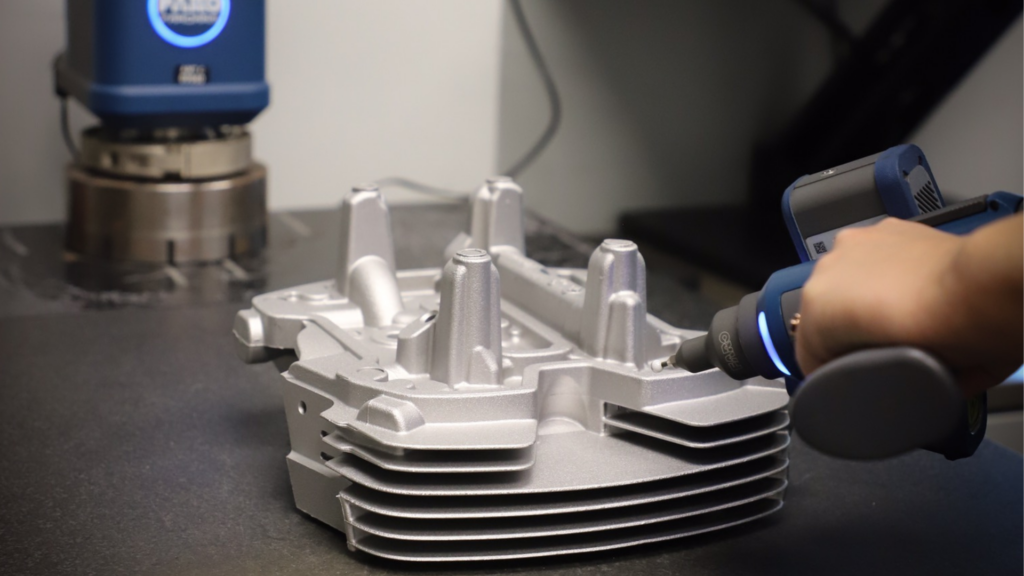

Because integrity is essential, WAF uses only modern impregnation processes, technology and equipment to seal your parts with high precision. Count on components that perform in the most demanding conditions.

One-stop shop

When you need leakproof components, WAF works across our family of foundries and supplier partners—from prototype to production—to meet your requirements, so you can keep production lines running. Performing casting capabilities like vacuum impregnation in-house means we can pass more value on to you.

Quality assurance and the certifications to prove It

WAF exacts rigorous quality control from design to delivery. We’re also ISO 9001, ISO 14001 and IATF 19649 certified.

Porosity sealing expertise

Our casting impregnation team has decades of combined experience. To strengthen that expertise, we use modern porosity sealing processes and technologies to produce superior leakproof castings that won’t fail on the line.

Learn more about our casting impregnation services

See how WAF’s in-house vacuum impregnation process can help leakproof your parts and production timelines.