World-class casting since 1909

Since Abraham Schwartz started Wisconsin Aluminum Foundry in 1909, we’ve helped industries achieve more success in casting by meeting every challenge with sophisticated problem-solving, agility and continuous improvement. Our commitment to better casting outcomes has takes us from a scrapyard business to a world-class foundry leader across diverse markets like automotive, agriculture, defense, energy and medical.

1909

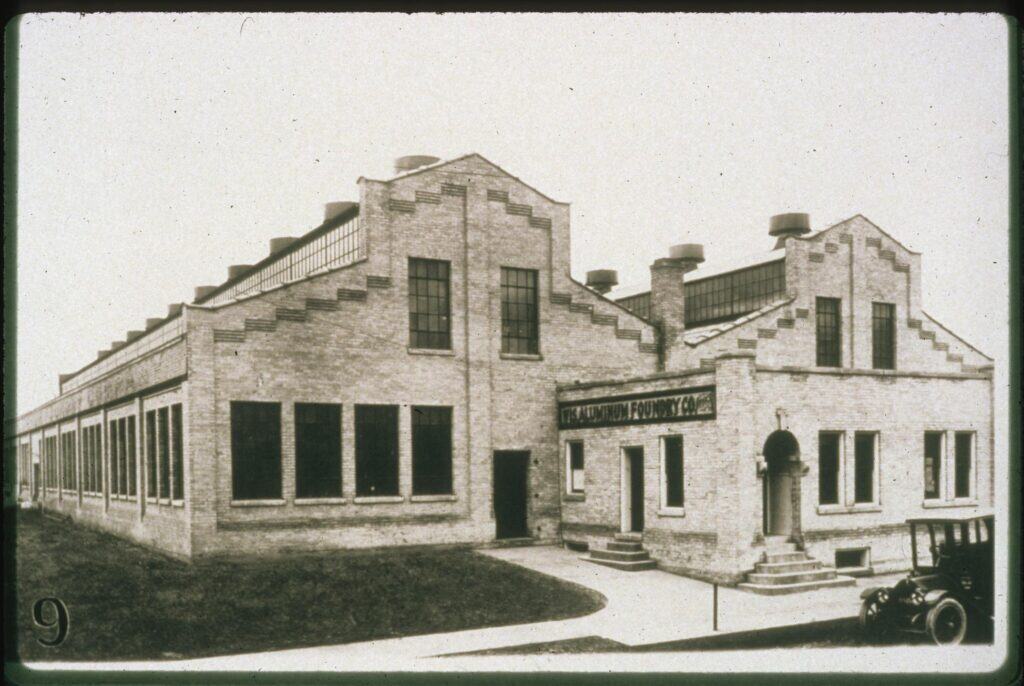

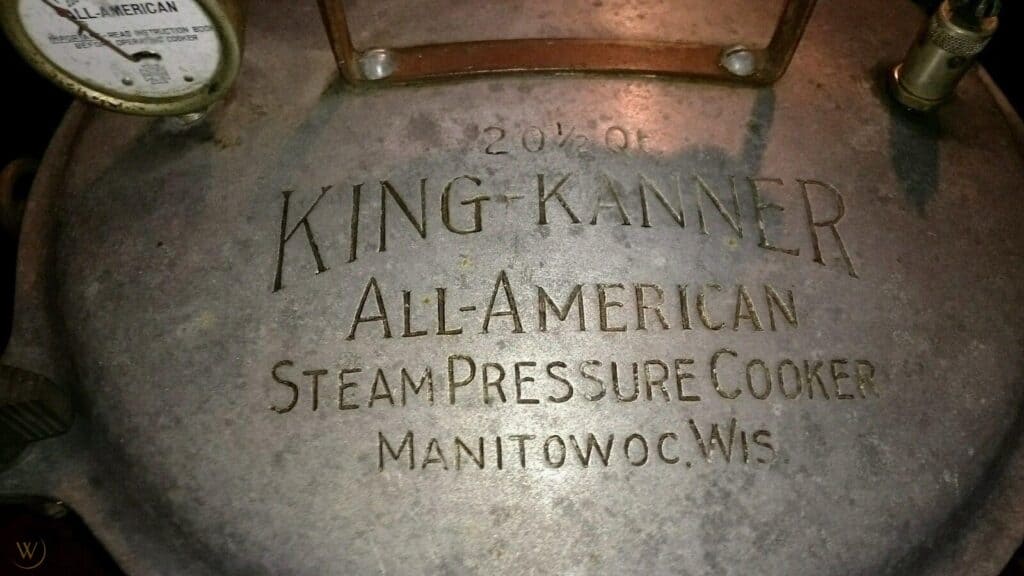

Abraham Schwartz builds a casting powerhouse

The son of Jewish Russian immigrants, Schwartz evolves his scrap yard to become Manitowoc Brass Foundry in 1909. It’s renamed Wisconsin Aluminum Foundry in 1912, committed to excellence, problem-solving and continuous improvement, which still stands today.

1929

1940

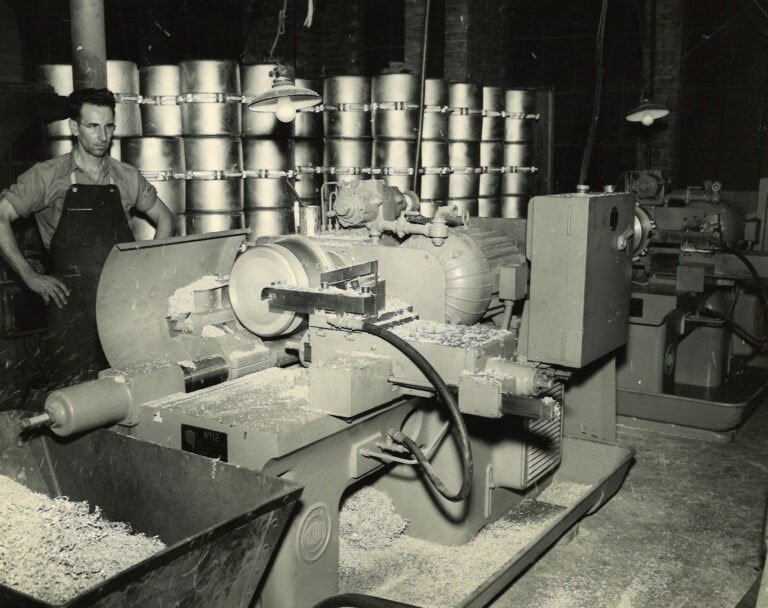

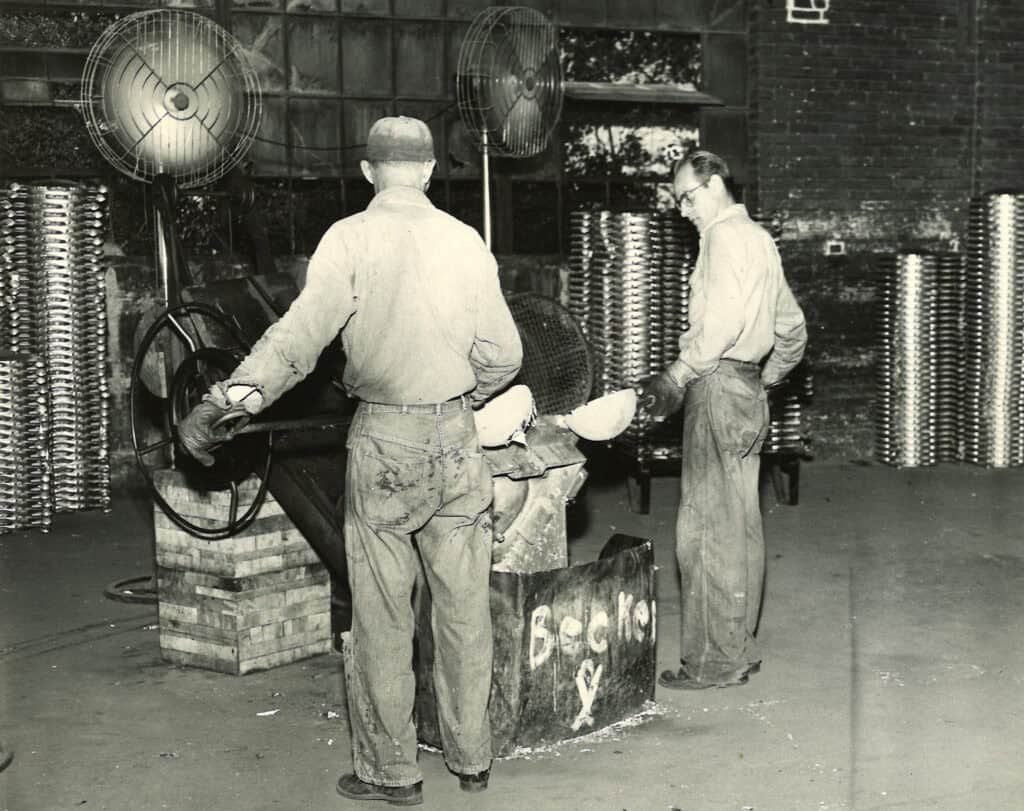

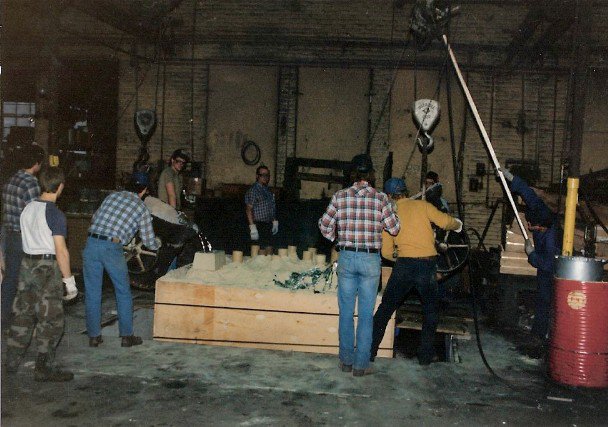

Building a dedicated workforce

WAF is 120 union workers strong, offering a competitive starting wage at 55 cents an hour for a 49-hour work week.

1970

1980

2003

2010

2021

Ready for a casting partner that elevates aluminum?

See how we can meet the demands of your tough challenges now and into the future. Contact us today!