The high-achiever in aluminum casting

An aluminum foundry casting what’s possible

When you have customers demanding equipment tough enough to weather all conditions, you need lightweight components cast to minimize corrosion. You need a partner who excels at solving the world’s most challenging casting problems.

World-class custom aluminum casting

No matter the challenge, Wisconsin Aluminum Foundry makes it possible to get the custom aluminum casting components you need to keep production moving, across industries like heavy-duty truck, automotive, marine, oil, agriculture, defense and medical.

Unmatched aluminum mold casting capabilities

We use four proven aluminum casting processes to cast a wider range of alloys. The engineering and design experts at Wisconsin Aluminum Foundry will work with your team to choose the best casting process to meet your requirements.

Air set

For complex custom aluminum parts that require strength, versatility and a superior finish

Green sand casting and green sand molding

For speed and agility, with intricate designs and production runs from low to high volume

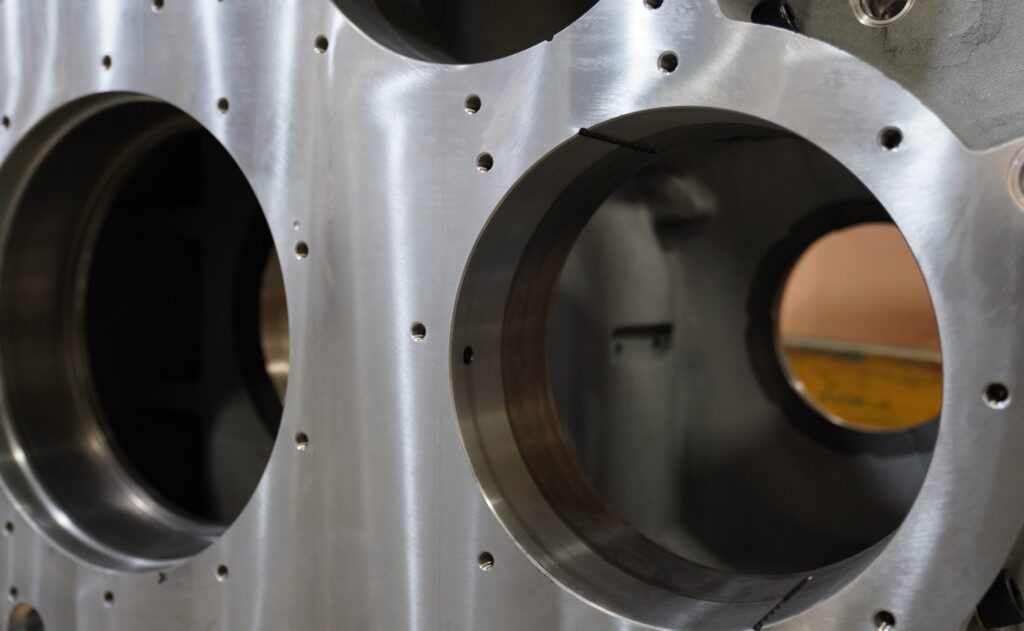

Low pressure permanent mold

For superior-quality custom aluminum components with precision, quality and dimensional repeatability

Your aluminum casting supplier, standing ready

Contact us today to see how we can meet the demands of even your toughest custom aluminum casting challenge.