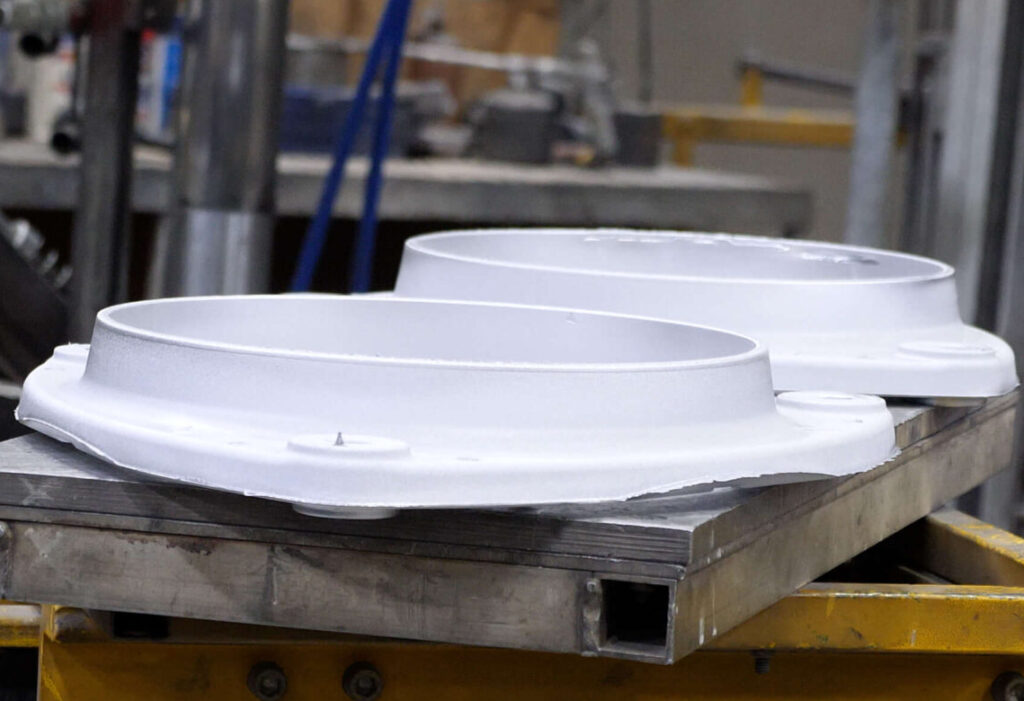

Low pressure permanent mold is ideal for symmetrical and cylindrical designs, delivering strong, uniform castings. In this innovative process, the furnace is pressurized and molten aluminum is delivered through the bottom of the mold, enhancing the quality of your casting.

Slow die filling and constant pressure help avoid the formation of oxides during solidification.

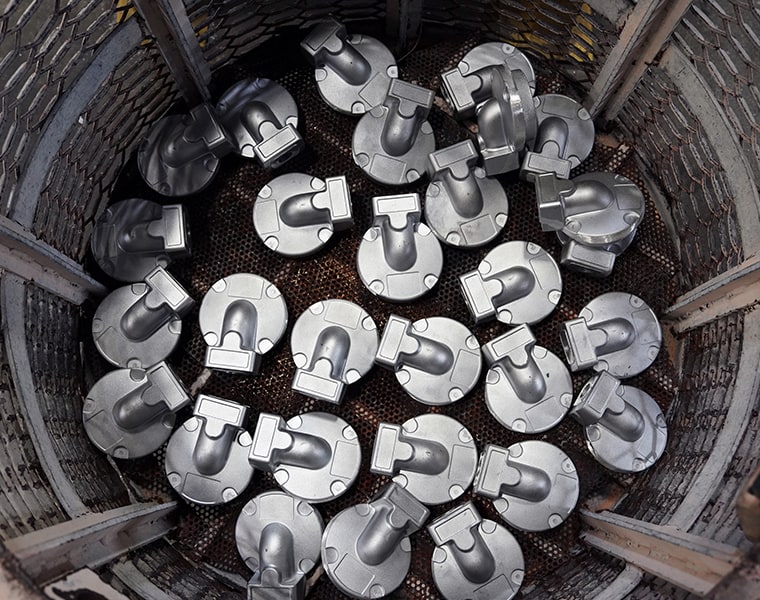

Low pressure permanent mold reduces gating systems by approximately 90%, significantly reducing melting and finishing costs.

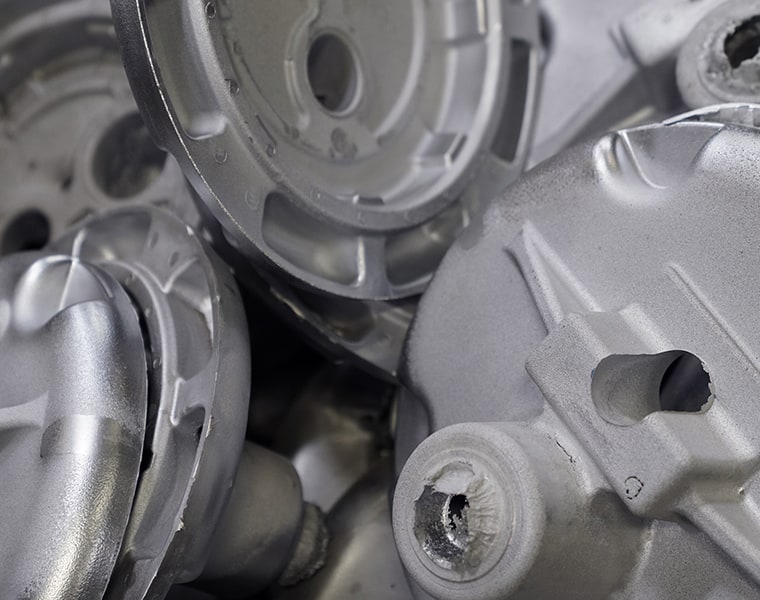

Suitable for applications requiring minimal porosity.

Want to know more about our capabilities?